Question from the Customer:

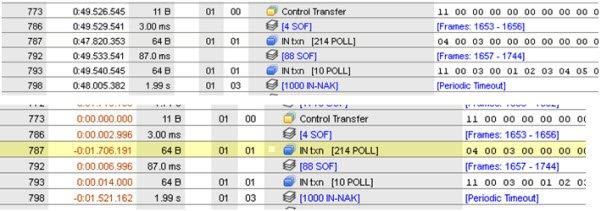

I am using the Beagle USB 480 Protocol Analyzer for a full speed USB trace. I want to measure the time between the control transfer and the second IN transfer. Doing that with the cursor shows a delta of 14 ms. However, the trace includes SOFs and polls that add up to over 200ms. The screen shots below the both normal view and the time reference view of a full speed USB trace.

Figure 1: Data Center Software: Full Speed USB Data with Normal View and Time Reference View

Figure 1: Data Center Software: Full Speed USB Data with Normal View and Time Reference ViewHow do I get the proper delays displayed in the timing column?

Also, to view only the setup and the data timing, I want to filter out both the SOFs and the NAKs. Using the LiveFilter tab in the Data Center Software, I see I can filter out the SOFs. How do I filter out the NAKs?

Response from Technical Support:

Thanks for your questions! The selected view determines how information is displayed. When you use the class view or the transaction view in the Data Center Software, the records may not be in time-order due to how the data is grouped for higher level parsing. You can see the records in time-order by switching to packet view, which disables the higher level parsing. Note that only the captures run in sequential mode can be viewed in packet view. Following is a summary of the capture views.

Figure 1: Data Capture Views

Figure 1: Data Capture Views

- Packet – Protocol-level decoding is performed - the records are in time-order. Collapsed groups, such as SOFs and IN-NAKs are broken up as necessary to ensure records are in timestamp order. Only captures run in Sequential Mode can be viewed in Packet View. For more information, please refer to section 6.2 of the Data Center Software User Manual.

- Transaction – Protocol-level decoding is performed - the records may not be in time-order. Collapsed groups are not broken up for time-order preservation. Since there is no time-order restriction, captures generally appear more compact in this view than in Packet View.

- Class – Class-level parsing is performed -the records may not be in time-order. Captures generally appear high-level and compact in this view. For more information regarding class-level decoding, please refer to section 6.9 of the Data Center User Manual.

For filtering out the NAK packets, go to the LiveFilter tab, click on the Packet radio button under the Protocol section and unselect the NAK checkbox.

Figure 2: Filtering out NAK with LiveFilter

Figure 2: Filtering out NAK with LiveFilterFor more information, please refer to the following documents:

We hope this answers your questions. If you have other questions about our protocol analyzers or other Total Phase products, feel free to email us at sales@totalphase.com or submit a request for technical support.

Figure 1: Configure SPI Mode via the Control Center Software Serial

Figure 1: Configure SPI Mode via the Control Center Software Serial Figure 2: Clock Polarities and Clock Phases of SPI Modes

Figure 2: Clock Polarities and Clock Phases of SPI Modes Figure 1: Aardvark Software SPI - Customize for Multiple Data Formats

Figure 1: Aardvark Software SPI - Customize for Multiple Data Formats Figure 1: Aardvark I2C/SPI Host Adapter

Figure 1: Aardvark I2C/SPI Host Adapter Figure 2: Promira Serial Platform

Figure 2: Promira Serial Platform Figure 1: Aardvark LabVIEW Driver

Figure 1: Aardvark LabVIEW Driver Figure 1: Komodo CAN Duo Interface

Figure 1: Komodo CAN Duo Interface Figure 1: Beagle USB 480 Power Protocol Analyzer-Ultimate Edition

Figure 1: Beagle USB 480 Power Protocol Analyzer-Ultimate Edition Figure 2: Beagle USB 5000 v2 Protocol Analyzer-USB 2.0 Edition

Figure 2: Beagle USB 5000 v2 Protocol Analyzer-USB 2.0 Edition Figure 3: Comparison Chart

Figure 3: Comparison Chart Figure 1: Cheetah SPI Host Adapter

Figure 1: Cheetah SPI Host Adapter Figure 1: Aardvark I2C/SPI Host Adapter

Figure 1: Aardvark I2C/SPI Host Adapter Figure 1: Flash Center Software

Figure 1: Flash Center Software

Figure 2: Serial Number of an Aardvark I2C/SPI Host Adapter

Figure 2: Serial Number of an Aardvark I2C/SPI Host Adapter Figure 1 - Control Center Serial Software with Master Register Read

Figure 1 - Control Center Serial Software with Master Register Read Figure 2: Control Center Serial Software in Batch Mode

Figure 2: Control Center Serial Software in Batch Mode Figure 1: Level Shifter Board

Figure 1: Level Shifter Board